How we helped our gas rig client repair their sea eroded drainage pipelines

We were tasked with repairing the drainage system on an unmanned offshore gas rig in the Southern North Sea.

A deep dive into the issue

The drainage system has sections of carbon steel piping fitted that required repair after suffering internal corrosion due to being in service for 12 years. They had been initially installed with a non-corrosion resistant alloy with an original design life of only 2 years.

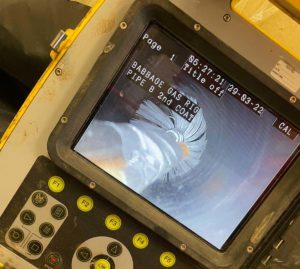

Internal corrosion and large loose scale deposits had caused frequent snagging and blockages. A full clean and removal along the length of carbon piping with replacement was required. Due to the location and nature of the system the Picote system was deemed the ideal solution.

Following a consultation with our experts, it was decided our brush coating offering would be appropriate for the repair and future proofing of their drainage system as the solution required less equipment and no lateral cutting to the pipework.

Getting on board!

Whatever the job requirements, we ensure our teams are trained in all safety aspects to the highest standards. Before even stepping foot on the rig, our teams undertook the appropriate safety training.

The 5 days of survival training included:

- BOSIET, this involved the team being in a helicopter shell lowered into a swimming pool and exiting while fully submerged.

- DONUT, training in quick exit from the gas rig into a survival raft

- MIST, survival at sea training.

The equipment was then packed and sent via boat to the rig, followed by the team a week later via helicopter from Norwich airport.

Resolution

We cleaned the pipes with a high-speed rotary chain and brush tools, taking care to disconnect the pipework to the macerator prior to descale to prevent possible damage of the waste handling system.

Outside connections were uPVC piping which required further care to clean as they were hard to reach transition and mastic joints, which must remain intact.

Brush coating offered minimal disruption, avoiding costly replacement. We are the leading certified Picote Brush CoatingTM business in the UK, land or sea we are experts in the remedial use of this system. The coating provides a damp proof, corrosion resistant, wear resistant and non-corrosive lining. This was a perfect solution for sea water eroded pipelines.

Our team worked solidly for 8 days aboard the rig to complete the job with great feedback from the client.

If you would like to know more about brush coating or how OnSite can help your gas rig maintenance, please contact us.

Download Case Study